On November 9 and 10, 2021, PetroVietnam Fertilizer and Chemicals Corporation (PVFCCo) organized an online session via Microsoft Teams on 5S skills training for all Office employees. The invited lecturer is Mr. Tran Thanh Quang – Technical Director – Viet Phat Solution Company.

During the session, Mr. Tran Thanh Quang provides the knowledge content, raising awareness, and the initial steps of the 5S program at the PVFCCo Headquarter: Actual situation of the working environment; Discipline, raising awareness and scientific and professional working spirit; Eliminate waste (work organization, unscientific arrangement, delay, waiting, errors, loss, damage, overwork, overwork, working attitude, reducing area…); Efficient and safe ways to improve labor productivity; Company image, organizational culture influence.

What is 5s? 5S is the name of a method to manage and arrange the working environment. 5S is an abbreviation of 5 Japanese words. These are Seiri (整理 Sort), Seiton (整頓 Arrange), Seiso (清掃 Clean up), Seiketsu (清潔 Take care of) and Shitsuke (躾 Get ready):

1. Sort – Sort: review, classify, select and remove unnecessary things in the workplace. This is the first step in the 5S methodology.

2. Arrange – Set in order: organize and rearrange items according to the criteria of easy to find, easy to see, easy to get, easy to return. Everything needs to be put in place to be convenient when it is required.

3. Cleanliness – Shine: regularly clean, clean, and clean everything that causes dirt at the workplace. This helps to create a clean, risk-reducing environment. In addition, it also improves the accuracy of the machinery to avoid dust.

4. Care – Standardize: continues to maintain the above 3S standards and implement them continuously. It sets the stage for the development into 5S.

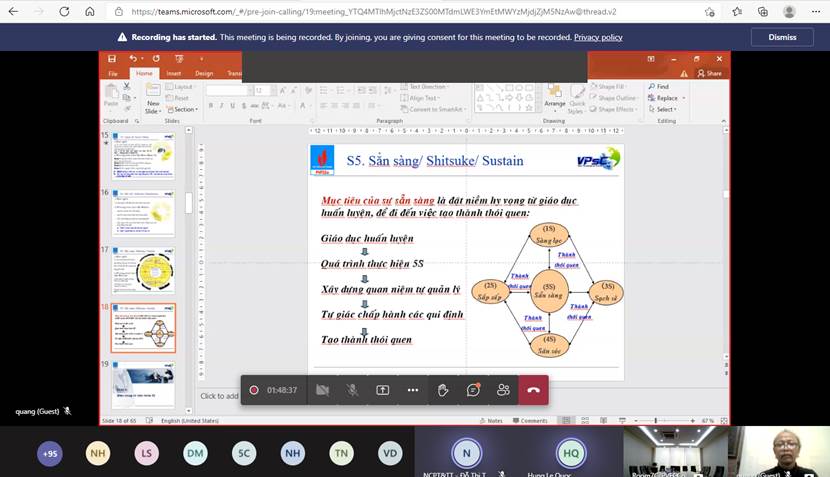

5. Ready – Sustain: practice, create self-discipline habits, maintain order and style.

5S also needs to follow workplace regulations to stay ready for production strictly. It is also necessary to arrange and classify from offices and construction sites to factories, where there is activity. The 5S method helps prevent the deterioration of offices and factories. It creates ventilation, convenience and avoids waste for businesses. A scientific working environment will improve psychology, conditions and increase labor productivity.

After the course, employees can understand and apply the 5S program in practice and raise their awareness of improving and maintaining a clean and orderly working environment according to the 5S program. Such is the importance of the 5s program, so PVFCCo needs to organize a class on 5s skills training for all employees at PVFCCo headquater.